SKINZIP® | Standing seam

Skinzip® is a cutting-edge standing seam system for roofs and façades, featuring long profiled trays that can reach lengths of 80 meters or more without interruptions. These trays can be produced either in the factory or on-site, significantly speeding up execution. The trays are connected by a seam of edges, using a mechanical continuous closing (like a zipper) on aluminum clips screwed onto the bearing structure. This ensures perfect fixation without drilling, resulting in a clean appearance with no visible fixing elements, a Skinzip®.

Skinzip® is a cutting-edge standing seam system for roofs and façades, featuring long profiled trays that can reach lengths of 80 meters or more without interruptions. These trays can be produced either in the factory or on-site, significantly speeding up execution. The trays are connected by a seam of edges, using a mechanical continuous closing (like a zipper) on aluminum clips screwed onto the bearing structure. This ensures perfect fixation without drilling, resulting in a clean appearance with no visible fixing elements, a Skinzip®.

THE ADVANTAGES

Because of its flexibility, Skinzip® standing seam system for roofs and façades represents a new range of construction possibilities. This constructive solution, of great elegance and technical performance, allows to cover “all” architectural forms, giving to the designer a huge creative freedom. This product is frequently used in an integrative way, having the roof and lateral façade working as a whole and in harmony. Roofs with an inclination from 1,5° to huge inclinations where the roof and the façade are only one. The technical performance of Skinzip® standing seam system is excellent and satisfies the most difficult requests of projects.

AESTHETIC AND FUNCTIONALITY

PROFILING AND FASTENING

Skinzip® profiles are obtained by cold profiling of metallic coils in factory or on-site with required width and length. Its geometry is specially designed to allow a mechanical closing between trays, working as a perfectly sealed “gutter”. The conical pieces are subject to a previous longitudinal cut in angle.

DESIGN

It is possible to cover the most audacious shapes, and with the same level of quality as far as finishing is concerned, even in more delicate details. Profile geometry of Skinzip® standing seam is very balanced, they have been designed in order to give to complexes covering sense of nobility and modernity.

SPEED

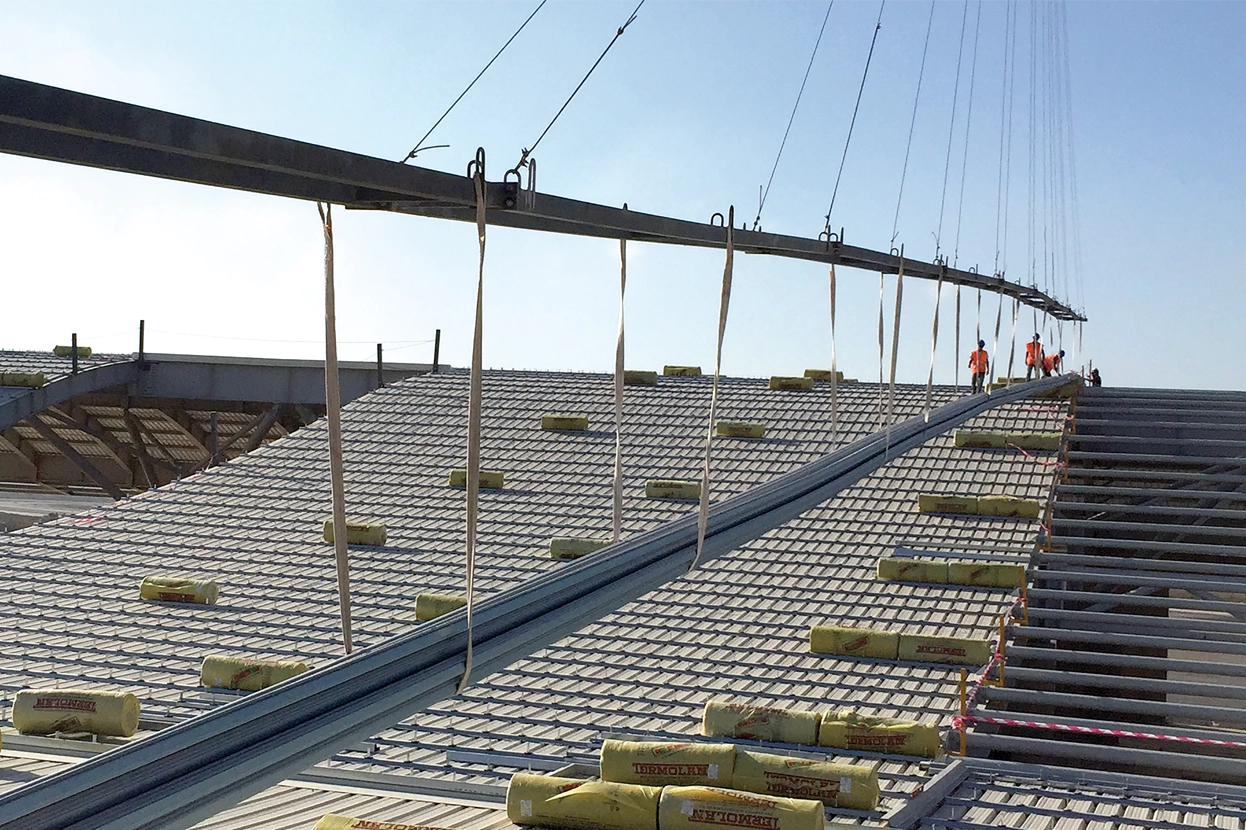

Skinzip® profiles are generally produced ON SITE, thus deleting several steps of manoeuvre and transport which can compromise the integrity of the sheets, and this with a considerable time saving. This way, Skinzip® profiled sheets can reach 80 meters length or even more, without interruptions. Thanks to their mechanical closing, the assembly and fixation of profiled sheets from Skinzip®, are extremely fast when compared with traditional fastening by screwing.

FLEXIBILITY

The assembly of Skinzip® standing seam system with other materials is easy and allows a large choice of possibilities to architects. The structures in steel, aluminium, wood, or concrete are thus perfectly integrated. The use of Skinzip® on pre-existing roofs, either metallic or in other materials is a privileged field of application in a way that it is not necessary to disassemble the previous roof, or to reinforce the sub-structure because of the lightness of materials. Besides the aesthetic renewal of the building, its thermal and acoustic comfort is significantly improved.

LIGHTNESS

Skinzip® is extremely lightweight, particularly when produced in aluminium, weighing less than 5 kg/m. It allows a great structural harmony and facilitate above all their handling and assembling. This feature allows to project big bays while totally respecting the calculation bases of the structure.

DURABILITY

The Skinzip® standing seam system offers unparalleled advantages in terms of durability and maintenance, setting it apart from other systems. Utilizing the highest quality materials, it ensures absolute sealing and comes with a warranty. The assembly process is seamless, without the need for drilling, and offers the flexibility to withdraw, replace, and dispose of profiles as needed.